Tribological Test Rigs

Tribological Test Rigs

As an operator of tribological test rigs, we know exactly what is important in the development and manufacturing of test rigs for tribological tests. In addition to standardized test rigs, we also design and build special test rigs on customer order. Here are some examples:

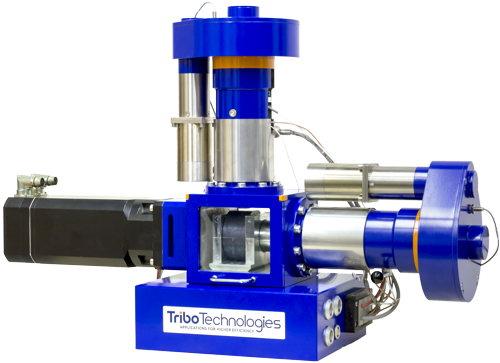

FE8 Rolling Bearing Test Rig

The FE8 rolling bearing test rig to DIN 51819-1 is used for the mechanical-dynamic testing of rolling bearing lubricants under conditions similar to those encountered in practice. The wear of the rolling bearing elements, the frictional behavior during the test and the occurrence of fatigue damage to the rolling bearing elements are used to assess the lubricant.

False Brinelling Test Rig

False brinelling damage can occur in rolling bearings if a stationary bearing is subjected to dynamic loads and/or pivoting movements with very small amplitudes. The dynamic loads and very small pivoting movements can be generated, for example, by machine and unit vibrations, but also during the transport of machines or vehicles by road, rail and ship.

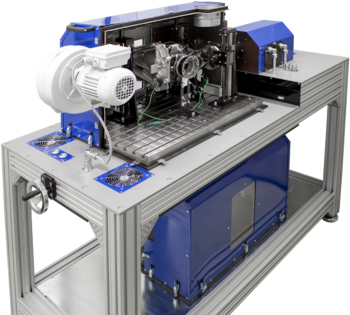

Radial Shaft Seal Test Rig

The testing and analysis of seals regarding leakage behavior, lubricant compatibility or robustness against acting media or particle is an important aspect in the development of sealing systems. A good leakage behavior is achieved when the sealing system consisting of seal, shaft, medium to be sealed, and ambient influences is precisely matched to each other.

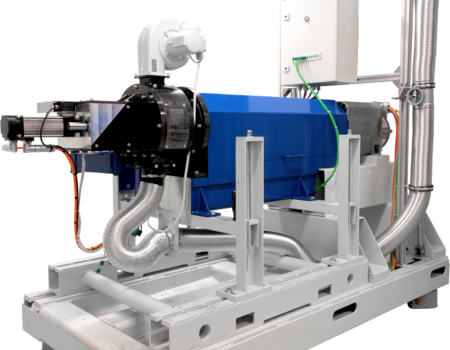

Friction Liner Test Rig

Friction linings are used in friction clutches or brakes. Friction clutches are often designed as friction shift clutches, which in vehicle applications must have a robust control quality and good shifting comfort. Both criteria require a positive gradient of the coefficient of friction. This is present when friction increases with increasing relative speed.

Whether friction, wear or fatigue life test rigs, tell us about your requirements and we will implement them. Our range of services around test rig design:

- design and development

- design, circuit diagram preparation and manufacturing

- draft and programming of the test rig software

- delivery, installation and training

- maintenance and repair

Do you have a test rig that no longer meets your current requirements? We would be pleased to take over the revision of your test rig.

Are you interested? Here you can contact us.

Download our brochure to get a comprehensive overview of our products and services. We can support you in the testing and simulation of your products. We also offer test rigs and simulation tools for integration into your development process or provide you with individual advice on your challenges. Take a look at it!

Download our brochure to get a comprehensive overview of our products and services. We can support you in the testing and simulation of your products. We also offer test rigs and simulation tools for integration into your development process or provide you with individual advice on your challenges. Take a look at it!